|

| OwenDuffy.net |

|

*** DRAFT ***

Initial experience with an AL80B revealed quite high case temperature during AM operation at 120W pY output, sufficient to burn skin with prolonged contact.

Measurements were made of the surface temperature of the case, and of the exhaust air stream. Highest case temperature was similar to exhaust air from the port near the valve, and temperature rise was consistently recorded at 45° above ambient.

In summer time, ambient temperatures reach 35° which with 45°rise gives a dangerous external case temperature. Even at 25° ambient, the resulting 70° case temperature is unsafe.

First step was to ascertain whether the amplifier efficiency was in line with expectations, and whether the existing cooling fan was moving the air as it should.

The amplifier was loaded (optimised) for 1000W pX (PEP) output on a pulsed sine wave. (Better efficiency ought be obtained if the PA was loaded for 500W pX (PEP), but the output circuit components do not allow that on 40m, the band of most interest.)

The study at Effect of reduced drive on Class B amplifier efficiency indicated that PA anode efficiency was as expected.

The ~200W power consumption at idle is also acceptable considering 75W of filament consumption, magnetising losses of a ~2kVA power transformer considering mains voltage at the time, and cooling fan.

The AL80B is an export model intended for markets using 50-60Hz. Supply frequency affects the rotational speed of AC induction motors such as used in the production PAPST 4800Z fan.

|

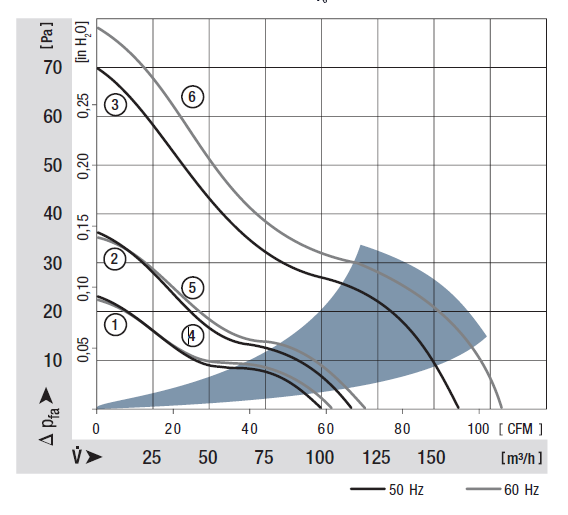

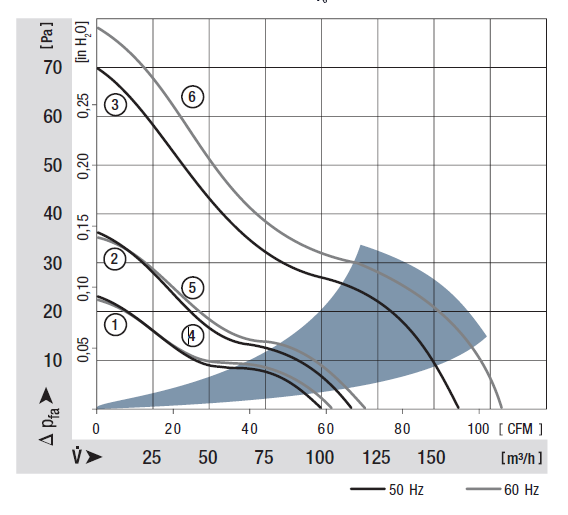

Fig 1 shows the characteristics of the PAPST 4800Z from PAPST's data sheet. Curve 1 is for the 4800Z on 115V/60Hz rated at 12W input, curve 2 is for the 4850 230V/50Hz (probably the same fan with a 230V winding). Fan pressure difference was measured at ~12Pa using a digital manometer, and flow rate measured at ~11l/s. It would appear from Fig 1 that the expected flow is 40m^3/hr (11l/s) which reconciles with measurement. (Though significantly lower throughput might be expected on 50Hz, it appears from the fan characteristics that with back pressure of 12Pa, the difference in throughput is quite small.)

The measurements of air flow and temperature rise at both output ports, and total input power indicates that most heat is removed in the air stream, around 85%.

Observations are:

These observations suggest that the fan is not adequate for the required operation. Much is made in the AL80B literature of how quiet the fan is, but it would appear quiet at the expense of adequate air flow in this scenario.

The analysis is a simple model, it assumes pressure at input and output the same, air density is taken as 1.2kg/m^3, heat capacity of the air is taken as 1012j/kg/K. The error in making these assumptions is small compared to the uncertainty of air flow measurements.

The question is whether a substitute fan can be installed that adequately cools the amplifier.

In view of the fact that the maximum case temperature is approximately equal to the worst case exhaust temperature, the thermal redesign can focus on the air stream.

A simple solution is to seek to increase the air flow proportionately to reduce the temperature rise to a maximum of 25° (max case temperature of 60°-35° ambient). To do that, the air flow needs to be increased to 45/25=180% of 11l/s or 20l/s.

The replacement fan needs to be metal to withstand the high IR radiation (it is very close to the valve), dimensionally identical, and needs to run on 120V 50/60Hz for compatibility.

|

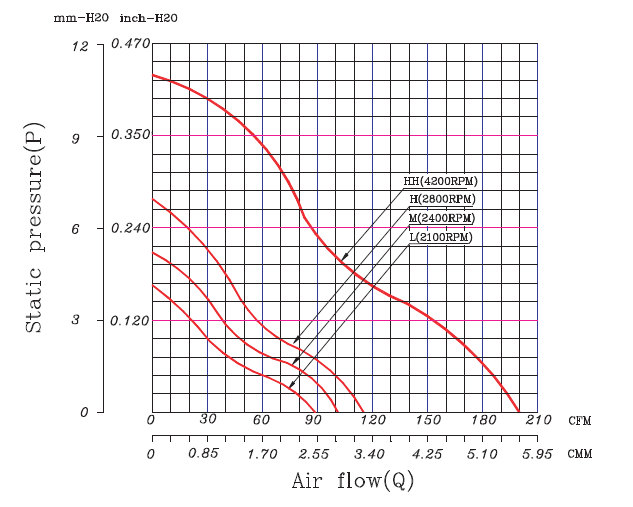

Fig 1 shows the characteristics of the 20W rated FAN12038AC115 here as an 'L' model fan.

With the higher air flow, we must expect a little more than the 11Pa observed with the original fan, a good design point might be 0.08" H2O, just above the third graticule line in Fig 1. Fig 1 suggests the fan should deliver around 1.13m^3/m or 19l/s.

The new fan was fitted, and temperature rise and airflow measured. Replacement was not trivial (due mainly to the short screws used in the original manufacture), but having made a screwdriver to suit the bodgy assembly, it was not too big a task.

In idle, temperature rise stabilised at 7.8° at 13.9l/s from the rear port, and 5.3° at 5.1l/s from the top port for a total heat output of 132W with AC input power of 197W, 84% of the heat leaves via the air stream.

Worst case temperature is the same as the exhaust temperature from the rear port, so worst case temperature rise is 7.8° for 197W total input power, or 0.040°/W.

At 120W carrier, temperature rise after 10 min key down was 25° which was the design objective.

Fan noise has increased markedly, but that is seen as a necessary element of the amplifier design and should indirectly assist in extending the life of valve seals by less temperature cycling. Whilst seal temperatures were not measured, the anode appears less red at the top that previously under the same output conditions.

A test was performed with continuous CW traffic at 800W PEP (rated CW power). Temperature rise appeared to stabilise at 18° after 10 minutes, though it may creep a degree or two over a longer time as the power transformer heats through.

The AL80B on 50Hz lacks sufficient cooling to safely run 120W AM.

Replacement of the cooling fan with one of nearly twice the capacity addresses the shortcomings, albeit with more fan noise.

| Version | Date | Description |

| 1.01 | 18/08/2013 | Initial. |

| 1.02 | ||

| 1.03 |

© Copyright: Owen Duffy 1995, 2021. All rights reserved. Disclaimer.